Why Garnet is the Best Abrasive for Waterjet Cutting

Several factors determine why garnet is the mineral of choice for waterjet cutting. Hardness, density, toughness, and particle size are the main elements that determine cutting speed and nozzle wear.

Garnet has proven itself to have the right balance of these factors to provide the strength and flexibility to cut through tough, thick materials or thin delicate ones. It cuts faster and more efficiently than other abrasives that can be too hard and erode the nozzle too quickly, too soft and break down into dust, or have blunt edges that slow cutting speed. Garnet also has the toughness to be processed into a wide variety of particle sizes, even the smallest, and still maintain its integrity and cutting power. Garnet is also cleaner and generates less dust compared to other abrasives, which helps protect the health of equipment operators.

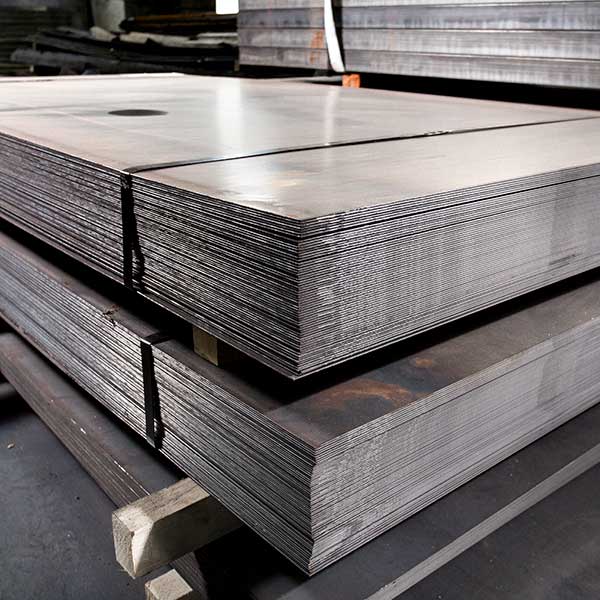

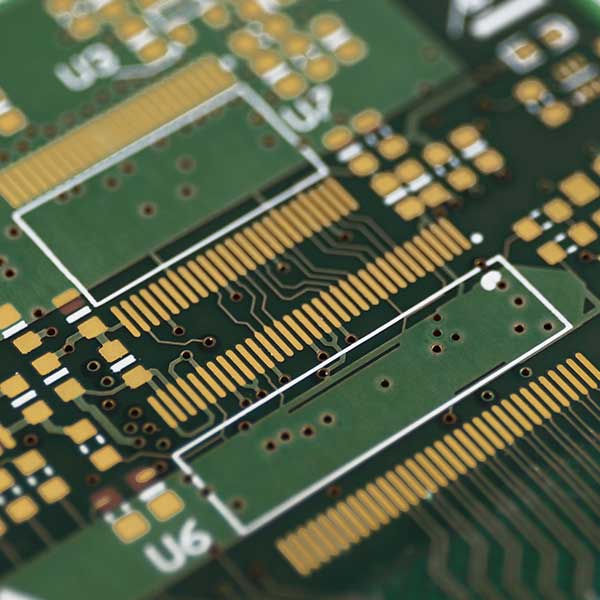

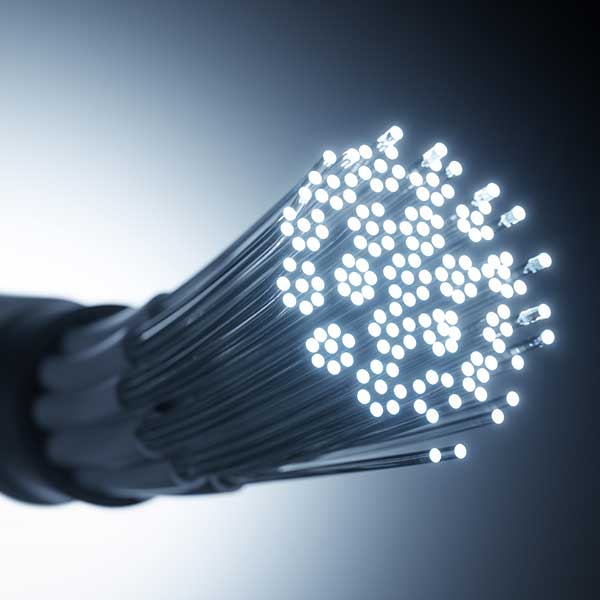

Whatever your industry, whatever materials you’re cutting, garnet is proven, more than any other abrasive, to perform with the speed, edge quality and surface finish you need for cutting a wide variety of materials, including:

Major Industries

Garnet Compared to Other Minerals

Mineral Hardness

The Mohs scale of mineral hardness characterises the scratch resistance of various minerals through the ability of a harder material to scratch a softer material. It was created in 1812 by the German mineralogist Friedrich Mohs and is one of several definitions of hardness in materials science. Mohs based the scale on 10 minerals that are all readily available. As the hardest-known naturally occurring substance, diamond is at the top of the scale.

Garnet is a naturally inert mineral that is a sharp, angular, 12-sided crystal (officially a rhombic dodecahedron) with a hardness of between 7.5 and 8.5 on the Mohs scale (where diamonds, which serve as the benchmark for hardness, rank as a 10).